Finishing

A printing firm in top gear!

In the case of Roularta Printing this is really no understatement. Seven rotary presses - including the impressive COLORMAN press - are running 24 hours a day.

The whole printing plant is a fine example of high tech: an adequate pre-press with several computer typesetting systems, sophisticated scanners and plate copiers, a state-of-the-art finishing department with automatic binding lines, three-sided cutters, packaging machines for plastic wrapping and shrink-wrapping, personalization, etc.

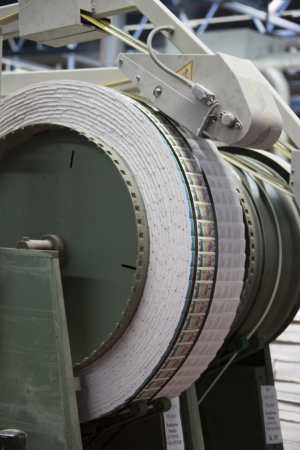

| Rotary trimmer |

| 1 rotary trimmer with several load possibilities: PrintRoll, MultiDisc 1 rotary trimmer with several load possibilities: PrintRoll, manual insert |

| UNIDRUM 420 gatherer |

| 1 “UNIDRUM” gatherer: 8 stations 7 load stations + 1 gluing station 5 PrintRoll-unwinder stations output: up to 30000 copies/h. |

| TEMPO gatherer |

| 1 “Tempo” gatherer: 10 stations 9 load stations + 1 gluing station 8 load stations + 2 gluing stations 7 PrintRoll-unwinder stations output: 10000-15000 copies/h. |

| M300 gatherers |

| 2 "M300" gaterers 10 stations 9 load stations + 1 gluing station 8 load stations + 2 gluing stations 1 plano feeder output: 7000-9000 copies/h. |

| PRIMERA stitcher |

| 1 “PRIMERA" gatherer: 10 stations 8 load stations + 2 gluing stations 7 PrintRoll-unwinder stations 1 “inkjet” print unit 1 stitcher 1 trilateral trimmer 1 "Perfetto" stacker 1 foil wrapper 1 shrink tunnel possibility for cross binding possibility for two-up output: 9000-14000 copies/h. |

|

Kolbus perfect binding |

|

9 load stations |

| 4 film wrapping machines (placed under film by unit) Type Sitma 80/950 (1) + type 950 (2) + type 950E (1) |

| load stations square back load station in-line and cross loader feeder disc feeder gadget feeder inkjet Practical output max. 15000 copies/h. Index film processing facility. |